-

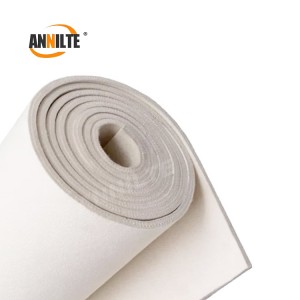

Annilte Heat Resistant White Rubber Food Grade Conveyor Belt for Sugar Factory Thailand

Annilte white rubber conveyor belt is widely used in food processing (e.g. sugar, salt, frozen fish) and pharmaceutical manufacturing (tablets, powder conveying).

1、No yellowing

Dedicated white rubber conveyor lines effectively eliminate surface staining issues.

2、Avoid dropping foam and dregs

blending wear-resistant formula belt, wear resistance increased by 50%, to avoid dropping foam and dregs, will not contaminate the material, and effectively improve the quality of the finished product of the material.

3、Food Grade

In strict accordance with the national food safety standards, the belt is made of food grade virgin rubber, and does not contain recycled materials and recycled rubber.

-

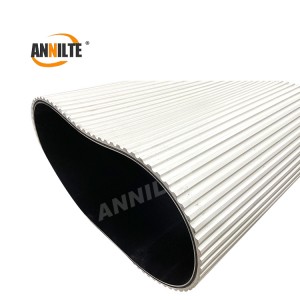

Annilte Fish Meat Separator Belt, Fish Deboning Machine Belt

Why Choose Annilte’s Fish Deboning Belts?

1、Salmon Processors (Norway/Chile) – High-speed deboning lines

2、Food-Safe & Easy to Clean – Compliant with FDA/USDA/EU standards, preventing contamination and simplifying sanitation.

3、Customizable Solutions – Available in various widths, lengths, and textures to fit different deboning machines.

4、Global Support & Fast Delivery – Stock Ready – Quick shipment (1-2 weeks vs. competitors’ 8+ weeks).

-

Gerber Perforated Conveyor Belts for Cutting Carbon Fiber Prepregs

Perforated conveyor belts have a wide range of applications in industrial automation equipment, such as food, medicine, tobacco, paper, printing, packaging and other industries.

Our Advantage

1、Wave uniform perforation

It is specially developed for Gerber cutting machine in the U.S.A. It adopts wave uniform cloth perforation, and the distance between the holes can reach about 1mm;

2、Strong adsorption force

The hole pattern is specially designed to have good adsorption performance to ensure that the carbon fiber prepreg will not shift during the cutting process.

3、Cutting resistance

The surface of the conveyor belt has a layer of Q-bouncing gel, good resilience, cutting resistance, no chips, which greatly extends the service life of the conveyor belt. -

Chinese Manufacturer Plaster Board Belts Gypsum Forming Belt

One-Stop Source for Gypsum Board Belting

Gypsum board manufacturers encounter various challenges, these include reliable transportation of heavy gypsum boards, minimizing board damage, ensuring precise alignment during forming, and maintaining consistent movement throughout the production line.Choosing the right conveyor belts for Gypsum/ plasterboard production and processing is crucial to ensure optimal performance and efficiency. -

Mirror conveyor belt for gypsum board production line

Features of mirror conveyor belt for gypsum board production line produced by Annilte:

1、Smooth as mirror

The hardness of the conveyor belt is increased, and the unique cooling device makes the surface of the conveyor belt as smooth as a mirror without any fine lines.

2、Flat joints

Adopting German superconducting vulcanization technology, the joints are flat and firm, which protects the efficient production of gypsum board.

3、No deflection

Infrared positioning + diagonal cutting process, the size of the conveyor belt is accurate, running without deflection.

4、Long life

Selected German imported pure raw material belt, does not contain calcium carbonate plasticizer, durable, aging-resistant, will not appear brittle fracture and other problems, greatly extending the service life of the conveyor belt.

-

Polyester Mesh Belt for Food and Vegetables Drying

Polyester mesh belt for food drying (polyester drying mesh belt) is a common food processing conveyor equipment, mainly used in food drying machines, drying ovens, ovens and other equipment, to undertake the transmission of food materials at the same time to withstand the high temperature and humid environment.

Wrapping process: new wrapping process researched and developed, preventing cracking, more durable;

Added guide bar: smoother running, anti-bias;

High temperature resistant stereotypes: updated process, the working temperature can reach 150-280 degrees;

-

Annilte white Peanut peeling machine belt for peanut sheller machine and Peanut groundnut peeling machine

Annilte specially developed a peanut sheller belt, the belt’s tooth depth and tooth pitch according to the peanut arc design, in the shelling is not easy to hurt the peanut, Precise peeling, half rate up to 98%,the surface is covered with nano-scale wear-resistant coating, which reduces the rate of slagging by 90% ,full numerical control refining process, light inspection of internal air bubbles after vulcanization, yield rate > 99%, to eliminate belt cracking and blistering problems.

-

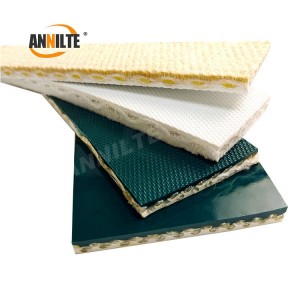

Annilte endless coil wrapper belts with TPU coating on both sides for steel plate and aluminum plate rolled

Advantage of coil wrapper belts:

1、Seamless

Seamless design has strong resistance to tension, not easy to stretch and break, suitable for harsh working environments.2、No deflection

One-piece molding design ensures thickness uniformity, smooth running and no deflection, avoiding burrs caused by serpentine deflection.3、Oil-and cut-resistant

The polyurethane material coated on the surface has good oil resistance, cut resistance, acid and alkali resistance. -

Anti-static Hard Wearing PVC Conveyor Belt Black

Key Benefits of Annilte’s Anti-Static Conveyor Belts

✔ Static Dissipation – Prevents static buildup, protecting sensitive products.

✔ Durable & Long-Lasting – Made from high-grade materials for extended service life.

✔ Customizable Solutions – Available in various widths, lengths, and thicknesses.

✔ Compliance with Industry Standards – Meets ISO, FDA, and other regulatory requirements.

✔ Reduced Downtime – Minimizes disruptions caused by static-related issues. -

Annilte nomex endless felt belt for heat transfer printing with stable quality

Our Heat transfer printing felts is made of 100% Nomex fiber, it is one of the import part of the Roller Heat Press Machine, Our felt Flat and smooth surface, there’s no tracking on the felts. It is perfect to avoid any possible marks on the fabrics processed. 2. Produced under a special heat-setting treatment, the felts run even under tension. And do not shrink while in use.

Heat transfer printing felts also called Nomex endless Felt, Calender heat press felt, sublimation heat press blanket, It is made of 100% aramid fiber (nomex). They are the most important component of the heat transfer printing machines which print the pattern from paper to fabric helping with pressure and temperature.

-

Steel cord rubber conveyor belt

Steel Cord Rubber Conveyor Belts – The Ultimate Heavy-Duty Material Handling Solution

Key Advantages of Our Steel Cord Belts

✔ Extreme Tensile Strength - Withstands up to 10,000 N/mm tensile force

✔ Long-Distance Performance - Ideal for 500m to 10km+ conveying systems

✔ Impact Resistant - Special rubber compounds protect against heavy loads

✔ Low Elongation - Maintains precise tension over long distances

✔ Energy Efficient - Reduced rolling resistance saves power costs -

Annilte Vacuum metal polishing machine belt

Vacuum metal polishing machine belt is mainly used for flat plate parts, stainless steel plate, carbon steel plate, aluminum plate, copper plate, titanium alloy all kinds of non-ferrous metals, rubber and plastic materials, such as deburring, polishing and grinding, the use of the surface is smoother. Vacuum metal polishing machine belt function: laser cutting, shearing under the material, stamping under the material, waterjet cutting, plasma cutting and other work surface pre-grinding, drawing, polishing, de-scratching, deburring, chamfering chamfering blunt processing. It is capable of strong adsorption conveying and feeding. Conveyor belt features: electromagnetic, strong permanent magnet adsorption conveying and feeding (applicable to carbon steel workpiece). Vacuum negative pressure adsorption conveying and feeding (applicable to stainless steel plate, copper plate, aluminum plate and other workpieces).

-

Silicone Conveyor Belt for Meat Processing

In the production of sausages, ham, bacon, meatballs and other meat products, conveyor belts need to meet the stringent requirements of food grade safety, grease resistance, anti-adhesion and easy cleaning. Food-grade silicone conveyor belts have become the preferred choice of the modern meat processing industry due to their excellent performance, ensuring that production efficiency and food safety standards are met.

-

Leather Wringing Machine Conveyor Belt for Leather Setting Out Machine

Compactor felts are key components in industrial compaction equipment, mainly used in the fields of paper, textile, composite material production, etc. They are used to optimize material compactness and surface flatness by absorbing moisture, transferring heat or providing uniform pressure under high pressure.

Features:

High temperature resistant (150°C, suitable for drying linkage line)

Anti-sticky (PU/PTFE coating to avoid wet leather sticking)

Anti-bacterial and anti-moldy (silver ion treatment, suitable for high humidity environments)

Highly breathable (accelerates water evaporation and shortens drying time) -

Customized Silicone Conveyor Belt for Vermicelli Machine

In the process of food processing, such as vermicelli, cold skin, rice noodle, etc., traditional PU or Teflon conveyor belt often encounters problems such as sticking, high temperature resistance and easy aging, which leads to decreased production efficiency and increased maintenance cost.

Food-grade silicone conveyor belt is becoming the first choice of more and more manufacturers due to its advantages of high temperature resistance (-60℃~250℃), anti-sticking and easy cleaning.